The Client:

A local contract manufacturer.

The Challenge:

The customer was tapping a "blind hole" in 17-4PH stainless steel and felt they were not getting appropriate productivity and tool life. They were using a high speed steel "OSG" 10-32 2B tap with an oxide coated surface.

The Solution

H&C Tool Supply recommended they test a Kennametal tap with a chromium carbide carbon (CRCC) coating. Kennametal technicians came to their facility and ran a test.

The Benefit:

The customer was very pleased with the results of the test:

- Speeds and feeds were more than doubled

- Tapping cycle was reduced from 1.06 minutes to 0.443 minutes

- Tap life increased from 164 holes per tap to 1000 per tap

- Tap usage per year on this job went from 25 taps to 4 taps

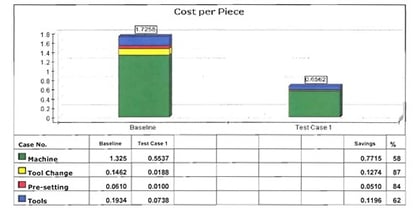

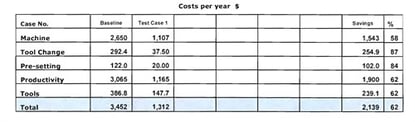

- Cost per piece went from $1.73 to $0.66

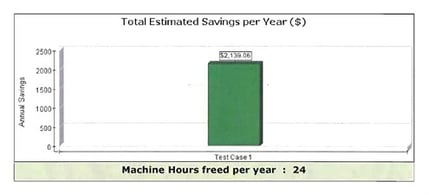

- There were 24 hours of machine time freed per year as well

The cost of the "OSG" tap was $15.86 per tap. The Kennametal tap cost was $36.92 per tap. The increased production and increased tool life, more than offset initial tooling cost.