The Client

Contract Manufacturer of Machined Components in Western, N.Y.

The Challenge

Shorten the cycle time of a roughing operation, improve tool life and increase throughput.

The Solution

H&C Tool Supply's representative recommended that the customer try a 1" diameter Kennametal "Harvi 2" 5-Flute End Mill with a 43 degree flute angle. The End Mill has a PVD coating of ALTIN (KC643M grade). This tool is used with coolant and is excellent for cutting steel, cast iron, stainless steels and titanium.

The Benefit

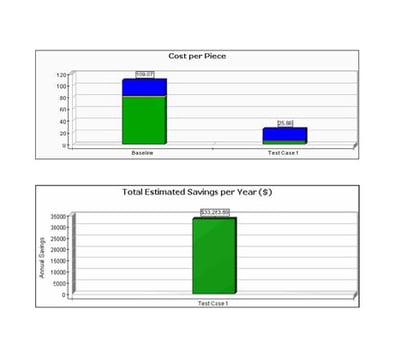

- Reduce roughing process from 45 minutes to 2.6 minutes

- Increased spindle speed from 1700 RPM to 2670 RPM

- Increased feed from 3.5 IPM to 60 IPM

- Increased SFM from 450 to 700

- Reduced number of passes from 2 to 1

- Reduced tool changes/purchased from 34 to 17 end mills per year

- Reduced scheduled machine time by 288 hours per year!!